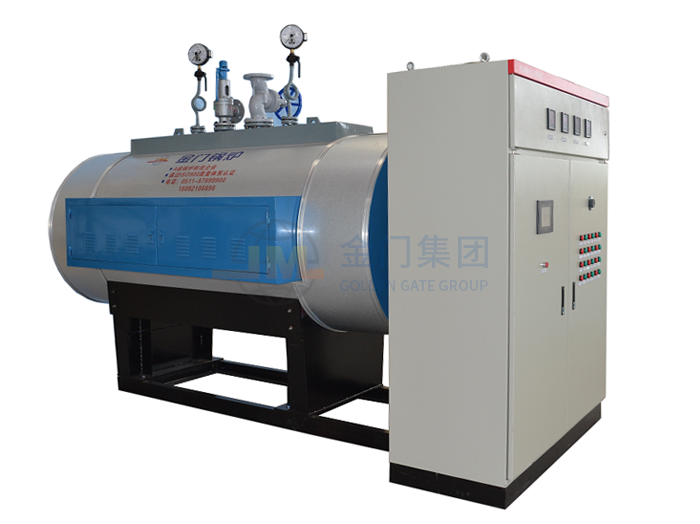

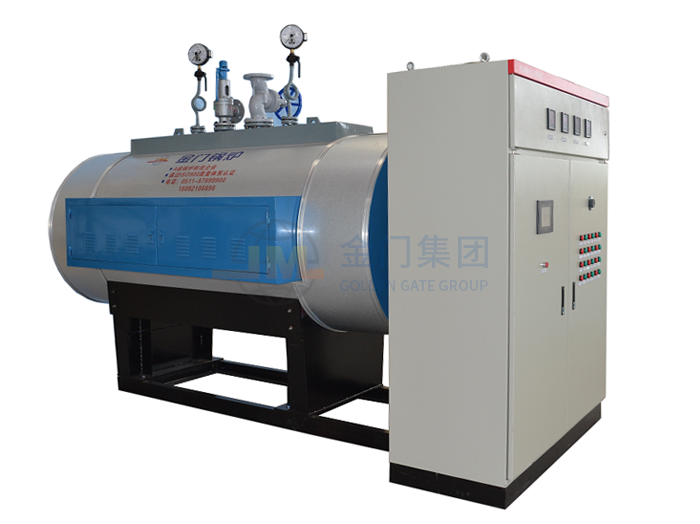

Description:

The new electric boiler adopts the advanced computer controller of the electric boiler, which has beautiful appearance and rich display. It can run continuously or work regularly without special personnel on duty. Usually, the operator only needs to press the "start button" to start the machine and press the "stop button" to stop the machine, which is very simple. The power components of the electric boiler are carefully made by CHINT GROUP and DELIXI ELECTRIC. The layout design is reasonable, and the wire diameter meets the requirements, which is convenient for maintenance; The electric heating pipe is made of 304 stainless steel pipe and filled with imported magnesium powder. It has good thermal conductivity and long service life. Use electricity reasonably, divide the electric power into several sections, and the controller will automatically cycle in and cut off the number of heating rod groups. Users can also manually determine the heating power according to actual needs, and press the corresponding cut-off switch. The boiler will adjust the electrical load according to the change of temperature difference load, so as to ensure the balance between power and load. The heating pipe is switched stage by stage, reducing the impact of the boiler on the power grid during operation.

Advantages:

1. High efficiency: the liner is made of carbon steel, which can be changed to galvanized or stainless steel liner according to user requirements. The electric heating tube (SUS304) adopts German manufacturing technology, with reliable quality and full heating, and the efficiency can reach 99%.

2. Power saving: compact structure, small volume and less energy consumption. Energy storage operation, saving electricity and low operation cost.

3. Safety: in case of overtemperature, overpressure, overcurrent, water shortage, short circuit and phase loss, automatic audible and visual alarm is adopted, and multiple protection systems are provided. According to the load change, start or stop each heating element step by step to avoid the impact on the power grid.

4. Convenience: the circuit design is reasonable, the wiring is neat, and the operation and maintenance are convenient. The control cabinet is designed with the upper and lower outgoing ways, which is convenient for users to choose. The connecting cable adopts multi strand copper core wire, which has high insulation, good heat dissipation and durability. The electric heating pipe is connected with the furnace body by flange, which is convenient for assembly and disassembly, replacement, repair and maintenance.

5. Durable: the electric heating element terminal adopts copper nose crimping, which is firm and not easy to heat. The layout of electric heating elements adopts the form of louvers, which is convenient for the heat dissipation of wiring terminals and can prolong the service life of electric heating elements.

6. Environmental protection: electricity as a heating source, clean and hygienic, environmentally clean, smoke-free, dust-free, noise-free, clean and hygienic.

7. Simple: small size, less land occupation, flexible space layout. There is no open fire and no special fire-fighting requirements.

8. Intelligence: the high-power electric hot water boiler adopts the separation method of furnace body and control cabinet, which avoids the heating of electrical components and affects the heating. Electromechanical separation, convenient for installation, wiring and maintenance. The 3.5-inch LCD color display screen is used to realize automation in the whole operation process, automatic grouping switching and automatic temperature regulation. It has multiple protection functions such as water shortage, automatic power failure alarm, power protection, leakage protection and so on.

Scope of application:

Industrial production, bathing, heating, planting and breeding, chemical production, brewing industry, food processing and other industries